From April 2012 our clinic expanded with the most modern German digital laser, CAD-CAM Amann Girrbach® Ceramill Motion 2. type computer controlled bur machine. Due to this the quality German precision micro-accuracy zirconium restorations’ price decreased significantly in our surgery.

You can read more about our own Amann Girrbach® machine: http://www.amanngirrbach.de/ What is zirconium-oxide?

Zirconium dioxide (ZrO2), sometimes known as zirconia (not to be confused with zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant stabilized cubic structured zirconia, cubic zirconia, is synthesized in various colors for use as a gemstone and a diamond simulant. Zirconium is a heavy metal 0.016 % of which is found in the earth crust and which, thus, occurs more frequently than the elements chlorine and copper. Its great hardness, low reactivity, and high melting point have made it the oldest mineral that can be found on the earth. Zirconium does not occur massively but is bound in minerals, mainly in zircon (ZrSiO4).

Zircon is also known as a precious stone whose color may vary from colorless white to brown, green, etc., depending on the traces of impurities. Due to their high optical density, zircon (and zirconia) gems have high refraction indices.

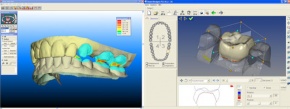

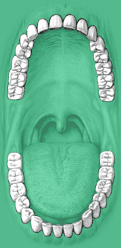

The prepared restoration doesn’t consist metal, every layers of it is tooth colored. This is the tooth type which imitates perfectly your own teeth’ layers and their natural transparency, thus these restorations are perfectly aesthetic and nevertheless they are also extremely durable. The most perfect border seal can achieve with the today’s most modern CAD/CAM computer controlled system. Based on the taken silicone impression from the teeth the prepared sample we digitalize with the help of a three dimensional laser scanning machine and the computer controlled bur machines make the restorations’ zirconium-dioxide skeleton, without human touch, excluded the errors. While at the pantograph controlled technology the zirconium-dioxide skeleton is made with hand-worked.

The result is the inimitable combination of the perfect accuracy and the high level aesthetics!

When recommended the zirconium-dioxide crown?

- your old metal ceramic crown’s change becomes necessary (its edge is gray metal stripe is visible)

- your tooth has been root canal treated, discolored

- in the case of any metal allergies (the zirconium-oxide does not contain metal)

The advantages of the zirconium-oxide crown:

- it is aesthetic and ultra-precise, because the zirconium prosthesis is are made with the above mentioned so called CAD/CAD procedure

- realistic: a zirconium prosthesis is practically indistinguishable from the real teeth

- reliable, long lasting: in the past 10 years there was made millions of zirconium crowns and fixed partial dentures around the world, to the biggest satisfaction of the patients. A lot of clinical studies have shown that the zirconium restorations are very reliable; they serve for many years and decades.

- it is 100% biocompatible: the zirconium oxide does not contain any metal, so the risk of the allergy is practically excluded. Meets to the stringent requirements related to the implantology, so the gingival is perfectly healthy around the crowns or the fixed partial dentures.

- due to the shoulder preparation the gingival remains healthy pink, it won’t be inflamed, won’t be turn blue

- the zirconium skeleton is made from such color, such as the ceramics (porcelain) veneer on it, but also the zirconium skeleton is completely individual, it has personalized color.

CAD-CAM technology:

Ceramill Motion 2 combines the 5-axis milling technique (wet/dry) with the wet-grinding technique in a compact machine. The machine can be used not only as a purely dry or wet system, but can also be operated in the wet and dry combination mode. In the combination mode operation can be easily changed between milling and grinding mode (by exchanging the blank holder). The choice of version depends on the indications, which the laboratory wants to fabricate on a CAD/CAM basis (refer to the indication matrix on the last page).

State-of-the-art 5-axis technology and proven stable, highly reliable precision components from the Motion 1 (e.g. Jäger® spindle) form the basis for a future-proof, robust dental CNC system, which is also optimally equipped for future areas of indications and materials (models, templates, full-denture prosthetics etc.).

The preparation is made with CAD-CAM computer controlled procedure: